Production Process

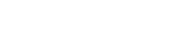

Corn wet milling process

For a better understanding of the wet milling process, corn grain must be considered as an element formed by four well defined macro structures:

Starch (Soft endosperm)

Found internally at the seed core. It is a polysaccharide formed by long chains of glucose molecules. Amylose and amylopectin can be identified in a regular and ordered strategy, called granules.

Gluten (hard endosperm)

Corn protein fraction, related to the typical carotene orange colour. It can be seen at the grain upper part and it has high insoluble protein concentration.

Germ

Compact addition, concentrating cereal fatty matter and soluble protein related to genetic codification. It is internally located at the seed base.

Fiber

Cellulosic matter, its higher concentration can be found outside the seed (husk).

-

MillingOpen, Close

In the first stage, corn is mixed with hot water to be softened. The reaction is a counter-diffusion in which the grain absorbs water, and the container is filled with salt and leachate soluble protein. To avoid microbiological degradation, sulphur dioxide is added in order to prevent alcoholic fermentation. Lactic bacillus activity is not inhibited since their lactic fermentation is favoured by lactic fermentation to grain softening speed.

In the first stage, corn is mixed with hot water to be softened. The reaction is a counter-diffusion in which the grain absorbs water, and the container is filled with salt and leachate soluble protein. To avoid microbiological degradation, sulphur dioxide is added in order to prevent alcoholic fermentation. Lactic bacillus activity is not inhibited since their lactic fermentation is favoured by lactic fermentation to grain softening speed. When corn has been into the water for around forty hours, it is ready to advance into the second stage: the first milling. In this stage mills are adjusted so that grain friction is generated. By doing this the grain explodes, giving way to the whole germ to appear. Special care must be taken so that germ does not break. If this takes place, the oil inside it may involuntarily spill. On the contrary, quality issues in final products may arise (rancidification). Separated germ is recovered taking advantage of its high oil content. Due to this, it has a lower relative density than the rest of the components. Thanks to these physical differences it is separated by hydro cyclone flotation. It is afterwards concentrated, drained, dried and dispatched as Germ Byproduct, a raw material for cooking oil extraction industry.

When corn has been into the water for around forty hours, it is ready to advance into the second stage: the first milling. In this stage mills are adjusted so that grain friction is generated. By doing this the grain explodes, giving way to the whole germ to appear. Special care must be taken so that germ does not break. If this takes place, the oil inside it may involuntarily spill. On the contrary, quality issues in final products may arise (rancidification). Separated germ is recovered taking advantage of its high oil content. Due to this, it has a lower relative density than the rest of the components. Thanks to these physical differences it is separated by hydro cyclone flotation. It is afterwards concentrated, drained, dried and dispatched as Germ Byproduct, a raw material for cooking oil extraction industry.

Once the product in transit has been degermed it undergoes a new and more aggressive milling process. Starch and gluten become solid in suspension, their size is less than 30 µm, while fiber (cellulosic matter) is torn into particles longer than 70 µm. Taking advantage of this difference in proportion, the separation of fiber and gluten and starch in suspension is made by means of a 50 µm strainer. Fiber is then washed, drained and pressed. At this stage, at the maceration process, water -enriched in leachate soluble protein from corn and after its concentration in falling film evaporators (concentrate liquor)- is added to the separate fiber in order to increase its protein content and hence be competitive with alternative fodder in cattle and pig farming. Once that fiber is mixed with concentrate liquor (steep water) it is dried in hot air co-current dryers. It is pelleted and sent as Gluten Feed (for livestock feeding).

Once the product in transit has been degermed it undergoes a new and more aggressive milling process. Starch and gluten become solid in suspension, their size is less than 30 µm, while fiber (cellulosic matter) is torn into particles longer than 70 µm. Taking advantage of this difference in proportion, the separation of fiber and gluten and starch in suspension is made by means of a 50 µm strainer. Fiber is then washed, drained and pressed. At this stage, at the maceration process, water -enriched in leachate soluble protein from corn and after its concentration in falling film evaporators (concentrate liquor)- is added to the separate fiber in order to increase its protein content and hence be competitive with alternative fodder in cattle and pig farming. Once that fiber is mixed with concentrate liquor (steep water) it is dried in hot air co-current dryers. It is pelleted and sent as Gluten Feed (for livestock feeding).

Once germ and fiber have been depleted from the process, and taking into advantage the subtle difference in density between gluten aggregates and starch granules, a light current rich in water and a heavy current rich in starch are separated by means of centrifugal forces. Gluten is drained in vacuum rotating filters, dried in tubular beam rotatory dryers, milled to controlled grading and finally dispatched as Gluten Meal, in order to be used as poultry feeding.

Once germ and fiber have been depleted from the process, and taking into advantage the subtle difference in density between gluten aggregates and starch granules, a light current rich in water and a heavy current rich in starch are separated by means of centrifugal forces. Gluten is drained in vacuum rotating filters, dried in tubular beam rotatory dryers, milled to controlled grading and finally dispatched as Gluten Meal, in order to be used as poultry feeding.

Starch obtained at the centrifugation stage is back washed in hydro cyclonic devices with treated water. It is finally delivered, as an emulsion (suspension) to the refinery plant for syrup manufacture, or to the starch plant for native starch or dry modified manufacture.

Starch obtained at the centrifugation stage is back washed in hydro cyclonic devices with treated water. It is finally delivered, as an emulsion (suspension) to the refinery plant for syrup manufacture, or to the starch plant for native starch or dry modified manufacture.

-

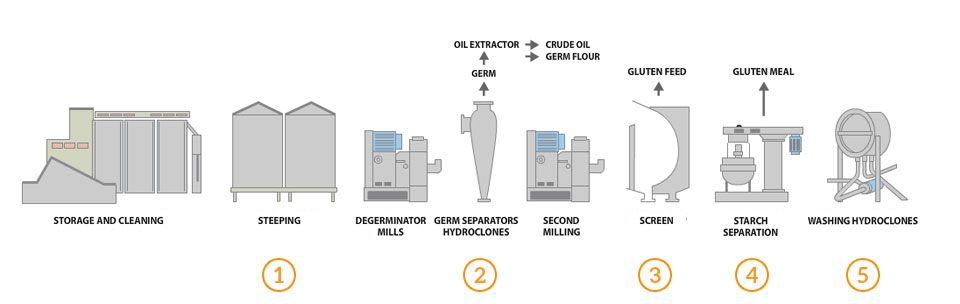

Glucose productionOpen, Close

Starch suspension obtained from wet milling, after acidizing, is hydrolysed in a continuous steam cook. In this cook, amylose and amylopectin chains in the starch granule are liberated. Then, when in touch with the acidic environment, they are cut in a series of sugary matters giving as a result a typical carbohydrate solution called "Acid glucose syrup".

Starch suspension obtained from wet milling, after acidizing, is hydrolysed in a continuous steam cook. In this cook, amylose and amylopectin chains in the starch granule are liberated. Then, when in touch with the acidic environment, they are cut in a series of sugary matters giving as a result a typical carbohydrate solution called "Acid glucose syrup". This syrup undergoes several filtration processes, activated carbon discolouration and cationic interchange operations. This is how colour generating matters and unwanted salt, flavors and other impurities are removed.

This syrup undergoes several filtration processes, activated carbon discolouration and cationic interchange operations. This is how colour generating matters and unwanted salt, flavors and other impurities are removed.

Final solid concentration is achieved by means of falling film vacuum evaporators. These evaporators get rid of water in the syrup in moderate temperature conditions, avoiding thermal product impairment.

Final solid concentration is achieved by means of falling film vacuum evaporators. These evaporators get rid of water in the syrup in moderate temperature conditions, avoiding thermal product impairment.

Finally, the product is sent to storage tanks. Even though physicochemical and microbiological properties are controlled during the entire operation, new measurements are carried out in the storage facilities to guarantee quality before its final delivery to the end customer.

Finally, the product is sent to storage tanks. Even though physicochemical and microbiological properties are controlled during the entire operation, new measurements are carried out in the storage facilities to guarantee quality before its final delivery to the end customer.

-

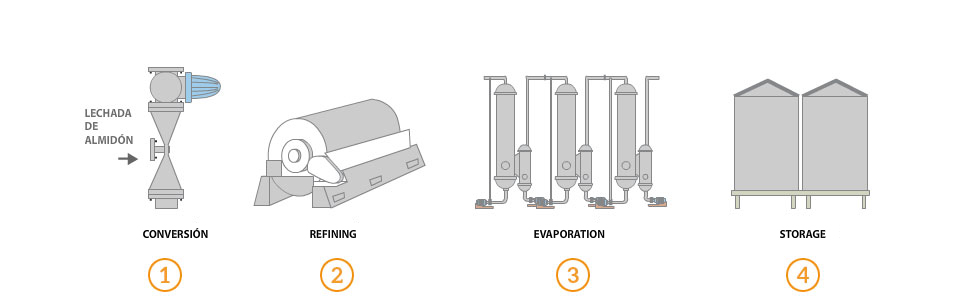

Fructose 55 manufacturingOpen, Close

Starch suspension obtained by wet milling is enzymatically hydrolysed in a venturi type continuous steam cook. In this cook, starch granules release both amylose and amylopectin chains, while added amylase enzymes reduce the chain length to produce a completely soluble syrup (Maltodextrin).

Starch suspension obtained by wet milling is enzymatically hydrolysed in a venturi type continuous steam cook. In this cook, starch granules release both amylose and amylopectin chains, while added amylase enzymes reduce the chain length to produce a completely soluble syrup (Maltodextrin). Once that starch suspension has been partially hydrolysed it relates to glucoamylase enzymes, giving way to an almost complete chain reduction to their primary links (dextrose).

Once that starch suspension has been partially hydrolysed it relates to glucoamylase enzymes, giving way to an almost complete chain reduction to their primary links (dextrose).

Dextrose syrup undergoes filtration, activated carbon discolouration an ionic interchange operations. This is how colour generating matters and unwanted salt, flavors and other impurities are removed.

Dextrose syrup undergoes filtration, activated carbon discolouration an ionic interchange operations. This is how colour generating matters and unwanted salt, flavors and other impurities are removed.

To achieve an improved efficiency in the following operations, the product is drained by means of falling film vacuum evaporation. This allows its concentration in moderate temperature conditions.

To achieve an improved efficiency in the following operations, the product is drained by means of falling film vacuum evaporation. This allows its concentration in moderate temperature conditions.

Dextrose obtained in syrup is the only one that features low sweetening properties compared to sugar cane. Nevertheless, by means of isomerase enzymes, most of it can be turned into levulose (high sweetening power sugar or monosaccharide). Due to this, fixed bedding enzymatic reactors are installed, so that when they get in touch with dextrose syrup levulose isomerization occurs. Due to the conversion degree achieved, the resulting product is called "Fructose 42".

Dextrose obtained in syrup is the only one that features low sweetening properties compared to sugar cane. Nevertheless, by means of isomerase enzymes, most of it can be turned into levulose (high sweetening power sugar or monosaccharide). Due to this, fixed bedding enzymatic reactors are installed, so that when they get in touch with dextrose syrup levulose isomerization occurs. Due to the conversion degree achieved, the resulting product is called "Fructose 42". Discolouration, ionic exchange and filtering operations take place once again, each one in turn in order to get rid of unwanted substances and polluting agents.

Discolouration, ionic exchange and filtering operations take place once again, each one in turn in order to get rid of unwanted substances and polluting agents.

A new concentration stage is applied to get rid of water in the syrup.

A new concentration stage is applied to get rid of water in the syrup.

Fructose 42 enters the fixed bedding absorption tower. This tower is fitted with chromatographic resin and has the ability to retain and separate levulose. The results of this process are a dextrose concentrate effluent that re-enters the filtering stage, and a different current generated by elution, highly rich in levulose.

Fructose 42 enters the fixed bedding absorption tower. This tower is fitted with chromatographic resin and has the ability to retain and separate levulose. The results of this process are a dextrose concentrate effluent that re-enters the filtering stage, and a different current generated by elution, highly rich in levulose.

In this process fructose 42 is mixed with the levulose enriched current created at the chromatographic separation stage. The goal is to achieve a 55% fructose syrup. With this concentration, its sweetening power is the same as sugarcane, making it a perfect sacarose substitute.

In this process fructose 42 is mixed with the levulose enriched current created at the chromatographic separation stage. The goal is to achieve a 55% fructose syrup. With this concentration, its sweetening power is the same as sugarcane, making it a perfect sacarose substitute.

A final polishing process is made to guarantee the organoleptic characteristics. Syrup is subject to a new demineralization by means of ionic interchange resins.

A final polishing process is made to guarantee the organoleptic characteristics. Syrup is subject to a new demineralization by means of ionic interchange resins.

Final solid concentration is achieved by means of falling film vacuum evaporators. These evaporators get rid of water in the syrup in moderate temperature conditions, avoiding thermal product impairment.

Final solid concentration is achieved by means of falling film vacuum evaporators. These evaporators get rid of water in the syrup in moderate temperature conditions, avoiding thermal product impairment.

The product is sent to storage tanks. Even though physicochemical and microbiological properties are controlled during the entire operation, new measurements are carried out in the storage facilities to guarantee the quality before its final delivery to the end customer.

The product is sent to storage tanks. Even though physicochemical and microbiological properties are controlled during the entire operation, new measurements are carried out in the storage facilities to guarantee the quality before its final delivery to the end customer.

-

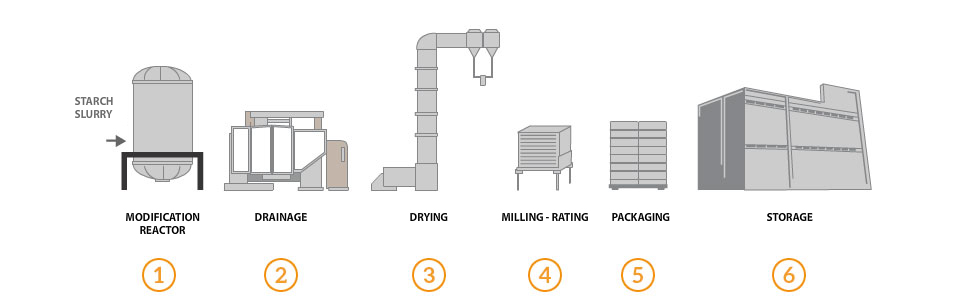

Modified starche manufacturingOpen, Close

Starch suspension enters a reactor. According to the desired modification type, it gets in touch with the proper reactives. This operation is not performed when dealing with native starch.

Starch suspension enters a reactor. According to the desired modification type, it gets in touch with the proper reactives. This operation is not performed when dealing with native starch.

Starch suspension, both in its native or modified state, is drained by means of a press filter. This filter allows humidity to be reduced until achieving a solid state (cake).

Starch suspension, both in its native or modified state, is drained by means of a press filter. This filter allows humidity to be reduced until achieving a solid state (cake).

In a continuous co current hot air flash dryer the starch cake reaches its final humidity to be marketed as dry powder.

In a continuous co current hot air flash dryer the starch cake reaches its final humidity to be marketed as dry powder.

These processes result in specific particle sizes, according to client's applications.

These processes result in specific particle sizes, according to client's applications.

Dry starch is taken to silos and from there fed to different facilities according each SKU (25 kg bags in pallets or different sizes flexible containers).

Dry starch is taken to silos and from there fed to different facilities according each SKU (25 kg bags in pallets or different sizes flexible containers).

Finished products are taken to the warehouses, awaiting for final physicochemical and microbiological approval, ready to reach end customers' houses with the proper quality assurance.

Finished products are taken to the warehouses, awaiting for final physicochemical and microbiological approval, ready to reach end customers' houses with the proper quality assurance.